Most startups think patents are about the product you can see. The device. The app. The final thing a customer touches. That is a mistake. In manufacturing and supply chains, the real value often lives somewhere else. It lives in the steps. The order. The timing. The tiny choices that make something cheaper, faster, stronger, or more reliable. This is process know-how. And once it leaks, you do not get it back. If someone else copies your process, they can build what you build without paying the price you paid to learn it. They skip the failures. They skip the wasted months. They skip the burned cash. Suddenly, your edge is gone.

Why the Process Is Worth More Than the Product

Most founders fall in love with what they can see. The finished part. The polished device. The unit that ships. That makes sense because that is what customers buy.

But in manufacturing and supply chains, the visible thing is often the least important part of the business.

The real value usually sits behind the curtain. It lives in how you make the thing, not the thing itself. It lives in the steps you chose, the order you locked in, and the shortcuts you earned through painful trial and error.

This is where long-term advantage comes from, and this is what competitors are always trying to steal.

The Hidden Work Customers Never See

Every strong manufacturing business has invisible work holding it together. Customers never see the early tests that failed. They never see the supplier who almost worked but did not.

They never see the process change that cut costs in half or doubled yield.

This hidden work turns into muscle memory inside your company. Engineers follow it without thinking.

Operators trust it because it works. Over time, it becomes normal. That is dangerous, because what feels normal to you may be extremely hard for others to figure out.

Actionable takeaway here is to slow down and write down what feels obvious. If a new hire would struggle to understand why a step exists, that step has value. That value deserves protection.

Products Can Be Reverse Engineered, Processes Usually Cannot

A finished product can often be taken apart. A competitor can buy it, scan it, test it, and learn a lot from it. Even complex hardware can be copied faster than most founders expect.

Processes are different. A process lives in time, motion, and decision-making. It is not just what happens, but when it happens and why. This makes it much harder to copy without insider knowledge.

This is why many copycats look identical on the outside but fail on cost, quality, or scale. They copied the product but not the process. Your job is to make sure they never get the missing pieces.

One practical move is to design processes that rely on internal judgment calls rather than fixed rules whenever possible. Judgment is harder to steal than instructions.

Small Process Tweaks Create Massive Margins

In manufacturing, small changes often create outsized results. A minor temperature shift.

A tighter timing window. A different order of assembly. These changes rarely look impressive on paper, but they can define your margins.

This is why process know-how compounds. Each improvement stacks on top of the last one. Over time, your company becomes hard to compete with, even if the product looks simple.

To protect this, treat every improvement as an asset. When your team finds a better way, pause and ask whether this is something a competitor would love to know. If the answer is yes, you should think about locking it down.

Supply Chain Choices Are Strategic Weapons

The suppliers you choose, the regions you work in, and the way you negotiate terms all shape your process advantage.

Two companies can use the same materials and still have wildly different outcomes because of how they manage relationships and timing.

These choices are often learned through hard conversations and failed deals. That pain turns into insight. That insight is valuable.

A smart habit is to separate who knows what inside your company. Not everyone needs full visibility into supplier terms, backup plans, or contingency steps. Limiting exposure reduces the chance of leaks.

Speed Comes From Process, Not Products

Founders often think speed comes from building faster products. In reality, speed comes from clean processes. When your process is tight, decisions are faster, mistakes are fewer, and scaling hurts less.

If a competitor copies your product but lacks your process, they will move slower. That delay is your advantage.

To reinforce this, invest time in stress-testing your process. Ask what breaks when volume doubles. Fix that before it becomes visible to the outside world. Quiet fixes are harder to track and copy.

Process Is What Investors Really Bet On

Experienced investors know products change. Markets shift. Features get replaced. What they care about is whether a team can repeatedly execute.

Execution lives in process. If you can manufacture reliably, source smartly, and adapt quickly, you can survive product pivots. Without that, even a great product can fail.

This means your process know-how is not just defensive. It directly impacts valuation. Protecting it protects future fundraising.

Founders should document core processes early, even if they feel messy. Clean documentation makes it easier to later turn that knowledge into defensible IP.

Competitors Chase Outcomes, Not Methods

Your competitors want your results. Lower costs. Better quality. Faster delivery. They usually do not know which steps create those outcomes.

If you leave clues everywhere, they will eventually connect the dots. If you are careful, they will chase symptoms instead of causes.

A simple rule is to never explain why something works unless you must. In demos, tours, or partnerships, focus on outcomes. Keep methods internal.

When Process Becomes the Product

In many successful companies, the process eventually matters more than the thing being sold. Contract manufacturers, logistics platforms, and advanced hardware firms all reach this point.

At that stage, your company is no longer just selling a product. You are selling a capability.

Capabilities are hard to build and easy to lose if not protected. This is where smart patent strategy becomes critical, because it allows you to lock down the how without exposing every detail.

If you want to see how modern teams protect process know-how without slowing down or revealing secrets, PowerPatent was built for exactly this challenge. You can explore how it works at https://powerpatent.com/how-it-works.

How Manufacturing Secrets Leak Without You Noticing

Most founders imagine leaks as dramatic events. A stolen laptop. A rogue employee. A competitor breaking into systems. That does happen, but it is rare.

The real danger is quieter. Manufacturing and supply chain secrets usually leak slowly, through normal business activity, while everyone believes they are being careful.

This section breaks down how those leaks actually happen in the real world and what founders can do to reduce risk without creating fear or friction inside the company.

The Illusion of Control Inside Growing Teams

Early on, everything feels contained. A few people, one workspace, shared context. Everyone knows what is sensitive. As the company grows, that shared understanding fades, but access often does not.

People keep old permissions. Documents get copied instead of linked. Knowledge spreads faster than intention. No one means harm, but harm does not require bad intent.

A useful habit is to assume that anything widely shared will eventually leave the building. If a process truly matters, it should live in fewer places and with clearer ownership. Control is not about mistrust. It is about clarity.

Suppliers Learn More Than You Think

Suppliers are not just vendors. Over time, they become observers of your process. They see volumes change. They notice timing patterns. They hear complaints and adjustments.

Individually, these signals seem harmless. Together, they paint a picture.

The risk increases when the same supplier works with your competitors. Even without sharing anything directly, patterns repeat. What worked for you becomes a suggestion for someone else.

One strategic move is to avoid letting any single supplier see the full picture. Split steps when possible. Keep certain logic internal. Treat suppliers as partners, but not as mirrors of your operation.

Factory Floors Are Information Highways

Factories are busy places. People talk. Operators move between companies. Consultants walk through lines and ask questions. Even a casual comment can reveal more than intended.

Founders often assume that physical processes are safe because they are complex. In reality, complexity attracts attention. The more unique your setup, the more memorable it becomes.

If you allow tours or external audits, decide in advance what is off-limits. Stick to that boundary. Consistency matters more than secrecy here. People respect clear rules more than vague caution.

Documentation Is a Double-Edged Sword

Good documentation is essential for scaling. It trains new hires. It reduces mistakes. It saves time. It also creates a clean record of how your company works.

That record is valuable. Too valuable to leave unprotected.

Many leaks happen when documents are shared for convenience. A deck sent to a partner. A process doc attached to an email. A screenshot dropped into chat.

The fix is not to stop documenting. It is to centralize and track access. If you know who can see what, you can manage risk without slowing execution.

Departing Employees Carry Invisible Baggage

When someone leaves, they take knowledge with them. Most of the time, they also take context. Even if they act ethically, memory cannot be erased.

The danger is highest when people leave during scale-up, when processes are still evolving and not yet locked down.

A smart practice is to treat exits as learning moments. Ask what they understood about the process. What felt unclear. What felt critical. Their answers reveal what knowledge is concentrated in people instead of systems.

Partnerships Create Unintended Exposure

Joint development, pilot programs, and strategic partnerships feel safe because they are collaborative. Everyone is aligned, at least at first.

But alignment changes. Strategies shift. People move roles. What was shared for one purpose may later be reused in another context.

Before entering any partnership, decide what process knowledge you are willing to share and what must stay internal. If you cannot clearly draw that line, the partnership may cost more than it gives.

Software Tools Quietly Spread Knowledge

Modern manufacturing relies on tools. Planning software, quality systems, analytics dashboards. These tools often connect to external services or vendors.

Every integration is a potential window. Not because vendors are malicious, but because data travels.

Founders should periodically review what data flows out of their systems. Not just customer data, but operational data. Process data is often more revealing than numbers on a spreadsheet.

Over-Explaining to Sound Credible

Founders and engineers love to explain how things work. It builds trust. It shows competence. It wins deals.

It also gives away leverage.

You do not need to explain every step to prove you know what you are doing. Results speak loudly. The more mature your company becomes, the less you should feel pressure to teach others how you operate.

Practice describing outcomes, not mechanics. This protects your process while still keeping conversations productive.

When Speed Becomes the Enemy of Secrecy

Startups move fast. That speed is a strength, but it creates shortcuts. Shortcuts often ignore security, access control, and long-term thinking.

Leaks often happen during rushed moments. A quick share to unblock someone. A temporary access that never gets removed.

Building small pauses into workflows can help. Not delays, but checks. A moment to ask whether sharing something is necessary or just convenient.

The Cost of Assuming Good Intent Is Enough

Most people involved in your business have good intent. That is not the issue. Systems built on intent alone eventually fail.

Protection requires structure. Clear rules. Thoughtful design.

This does not mean turning your company into a locked box. It means deciding what truly matters and treating it with care.

If your manufacturing or supply chain process gives you an edge, it deserves the same attention as your product roadmap.

This is where many founders turn to modern patent strategies that protect how things are done without forcing public exposure. PowerPatent helps teams do this in a way that fits fast-moving companies. You can learn more at https://powerpatent.com/how-it-works.

Protecting Know-How Without Slowing Down Your Company

Most founders fear that protecting process know-how will slow everything down. They picture heavy rules, endless approvals, and legal work that drags on for months. That fear is understandable, but it is also outdated.

Modern companies can protect what matters while still moving fast. The key is to stop thinking of protection as a legal task and start thinking of it as a design choice. When protection is built into how the company operates, it stops feeling like friction and starts feeling like leverage.

Protection Starts With How You Think, Not What You File

Many teams wait too long because they think protection begins with paperwork. In reality, it begins with awareness.

When a team understands that process knowledge has value, behavior changes naturally. People become more thoughtful about what they share and how they share it. This shift alone reduces risk without adding a single meeting or rule.

A simple internal habit is to regularly ask one question during reviews or retrospectives. What did we learn this month that a competitor would love to know. The answers reveal what needs protection long before lawyers get involved.

Speed Comes From Clarity, Not Openness

Founders often equate openness with speed. They believe that sharing everything with everyone keeps teams aligned and fast. That can work early on, but it breaks at scale.

True speed comes from clarity. When people know exactly what they need to know and nothing more, decisions get faster, not slower.

Designing access intentionally helps here. Engineers see engineering detail. Operators see operational steps. Strategy stays contained. This is not secrecy for its own sake. It is focus.

Build Protection Into Daily Workflows

The best protection systems are invisible. They do not rely on memory or discipline. They rely on structure.

For example, when documentation lives in one controlled system instead of scattered files, protection becomes automatic. When process changes require a short internal review, knowledge gets logged and ownership becomes clear.

These small design choices add almost no time, but they dramatically reduce leakage.

Treat Process Changes Like Product Changes

Most companies treat product changes with care. They review them, test them, and track them. Process changes often happen informally, through chats or quick decisions on the floor.

That informality is where value leaks.

When a process change improves cost, quality, or speed, it should be treated as a real asset. That means capturing why it works and who owns it.

This does not mean slowing down experimentation. It means slowing down forgetting.

The Difference Between Sharing and Teaching

Your company will need to share information. With partners. With suppliers. With customers. The goal is not to stop sharing. The goal is to stop teaching.

Sharing outcomes is safe. Teaching methods is risky.

For example, telling a partner that your lead times improved is fine. Explaining the internal sequencing change that made it happen is not.

This mental line helps teams communicate confidently without oversharing.

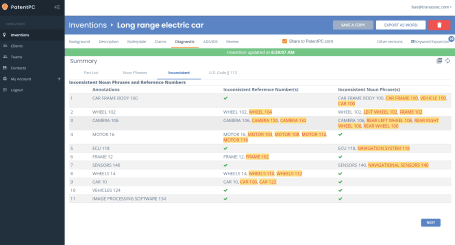

Legal Protection Should Match How Fast You Move

Traditional patent processes are slow because they assume companies move slowly. That mismatch creates frustration and delays.

Modern teams need protection that keeps pace with iteration. That means capturing ideas as they evolve, not after everything is finalized.

When protection keeps up with development, it stops being a blocker. It becomes a record of progress.

This is why founders increasingly use tools that fit into their workflow instead of pulling them out of it.

You Do Not Need to Expose Everything to Protect It

One common myth is that protecting a process requires revealing it in full detail. That fear pushes founders toward trade secrets only, which are fragile and hard to enforce.

In reality, smart protection focuses on the core insight, not every detail. The goal is to lock down the idea that makes the process work, not the entire manual.

This balance lets companies protect their edge while keeping sensitive execution details internal.

Protection Reduces Stress as You Scale

As companies grow, anxiety grows with them. Founders worry about who knows what. They worry about leaks they cannot see.

Having a clear protection strategy reduces that stress. It creates confidence that even if someone leaves or something leaks, the core advantage remains safe.

That peace of mind has real value. It frees founders to focus on growth instead of fear.

Strong Protection Improves Negotiating Power

When your process know-how is protected, conversations change. Partnerships become more balanced. Acquisitions become more serious. Investors ask better questions.

You are no longer hoping others respect your work. You have leverage.

This leverage does not come from being aggressive. It comes from being prepared.

The Best Time to Protect Is Before You Feel Ready

Most founders wait until something feels complete before protecting it. By then, it may already be exposed.

Protection works best when it runs slightly ahead of comfort. When you capture ideas while they are still forming, you create a time advantage.

That advantage compounds. Each protected insight builds a stronger wall around how your company really works.

Protection Should Feel Like Progress, Not Paperwork

If protection feels heavy, something is wrong. It should feel like momentum. Like clarity. Like putting a flag in the ground and saying this matters.

The right approach turns protection into a natural part of building, not a separate chore.

PowerPatent was built with this exact philosophy. It helps founders protect process and supply chain know-how quickly, clearly, and without slowing teams down. You can see how it works at https://powerpatent.com/how-it-works.

This section goes deep, but there is more to cover, including how to decide what to patent versus what to keep internal and how to align teams around protection without killing culture.

Wrapping It Up

Most manufacturing and supply chain advantages are quiet. They do not show up in marketing. Customers never talk about them. Competitors rarely understand them until it is too late. Yet these hidden processes are often the reason a company survives while others fail. Founders spend years earning this knowledge. They burn time, money, and energy learning what works and what does not. Letting that hard-earned insight leak away is one of the most expensive mistakes a growing company can make. Protection does not mean paranoia. It does not mean slowing down or locking people out. It means being intentional. It means knowing which parts of your operation truly matter and treating them with the respect they deserve.